+91 - 96540 46212

Advance Rub Cork Industries is a ISO 9001:2015 certified company engaged in manufacturing rubberised cork sheets, gaskets, seals, frames, components & articles mainly being used in sealing, insulating material for electrical transformers, automotive and also various oil filled equipment and machinery. Advance Rub Cork Industries is supplying its products to various central government of India organizations, state run companies, major power transformer manufacturers both nationally and internationally.

Our facility is fully equipped with Modern European machinery which is known for high precision manufacturing which results in very high quality products. These standards are tested in house in fully equipped testing lab which is equipped with NABL accredited lab testing equipment before despatching to the customer.

Advance Rub Cork International offers an extensive range of rubberized cork products that cater to various industries and applications. Our product line includes:

Rubberised Cork Grinder are used in Glass Polishing. Sizes and thickness are custom made upon request.

We collaborate closely with our clients to develop tailored solutions and products that meet their specific requirements.

All information and recommendations contained in this specification are to the best of our knowledge.

| Specifications for Rubber Cork Products | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| SR. NO |

Grades & Properties | ARCI - NOR (Non Oil Resistant) |

ARCI - GOR (Good Oil Resistant) |

ARCI - VGOR (Very Good Oil Resistant) |

||||||

| Grades Offered | ARCI 50A | ARCI 70A | ARCI 80A | ARCI 50B | ARCI 70B | ARCI 80B | ARCI 50C | ARCI 70C | ARCI 80C | |

| 1 | Hardness IRDH | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 |

| 2 | Dimensional charge percent Max. | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 3 | Tensile Strength kPa. Min | 650 | 900 | 1250 | 700 | 1250 | 1550 | 1250 | 1550 | 1900 |

| 4 | Compressibility (at 2800 KPa) Percent |

45-65 | 30-45 | 15-30 | 45-60 | 35-50 | 25-35 | 35-45 | 25-35 | 15-25 |

| 5 | Recovery, Percent, Min | 80 | 80 | 75 | 80 | 80 | 75 | 80 | 80 | 75 |

| 6 | Compression Set Percent Max. | 90 | 90 | 90 | 80 | 85 | 90 | 80 | 85 | 90 |

| 7 | Chemical Test on water extracts | |||||||||

| a) PH. where applicable | 5.0 to 8.5 | 5.0 to 8.5 | 5.0 to 8.5 | |||||||

| b) Chloride content(as chloride ion) | 0.2 percent, Max | 0.2 percent. Max | 0.2 percent, Max | |||||||

| c) Sulphate content(as sulphate ion) | 0.2 percent, Max | 0.2 percent, Max | 0.2 percent, Max | |||||||

| 8 | Gaskets suitable for |

General purpose only Light electrical and general automotive industry |

Automotive Industry Light electrical and general automotive industry | Automotive industry Heavy electrical industry Ship building and maintenance Aircraft industry | ||||||

| SR. NO |

Specifications for Rubber Cork Products |

ARCI - NOR (Non Oil Resistant) |

ARCI - GOR (Good Oil Resistant) |

ARCI - VGOR (Very Good Oil Resistant) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Grades & Properties | ARCI - NOR (Non Oil Resistant) |

ARCI - GOR (Good Oil Resistant) |

ARCI - VGOR (Very Good Oil Resistant) |

|||||||

| Grades Offered | ARCI 50A | ARCI 70A | ARCI 80A | ARCI 50B | ARCI 70B | ARCI 80B | ARCI 50C | ARCI 70C | ARCI 80C | |

| 1 | Hardness IRDH | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 |

| 2 | Dimensional charge percent Max. | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 3 | Tensile Strength kPa. Min | 650 | 900 | 1250 | 700 | 1250 | 1550 | 1250 | 1550 | 1900 |

| 4 | Compressibility (at 2800 KPa) Percent |

45-65 | 30-45 | 15-30 | 45-60 | 35-50 | 25-35 | 35-45 | 25-35 | 15-25 |

| 5 | Recovery, Percent, Min | 80 | 80 | 75 | 80 | 80 | 75 | 80 | 80 | 75 |

| 6 | Compression Set Percent Max. | 90 | 90 | 90 | 80 | 85 | 90 | 80 | 85 | 90 |

| 7 | Chemical Test on water extracts | |||||||||

| a) PH. where applicable | 5.0 to 8.5 | 5.0 to 8.5 | 5.0 to 8.5 | |||||||

| b) Chloride content(as chloride ion) | 0.2 percent, Max | 0.2 percent. Max | 0.2 percent, Max | |||||||

| c) Sulphate content(as sulphate ion) | 0.2 percent, Max | 0.2 percent, Max | 0.2 percent, Max | |||||||

| 8 | Gaskets suitable for |

General purpose only Light electrical and general automotive industry |

Automotive Industry Light electrical and general automotive industry | Automotive industry Heavy electrical industry Ship building and maintenance Aircraft industry | ||||||

| SR. NO (1) | Specifications for Rubber Cork Products |

Type A (None-Oil Resistant) | Type B (Good Oil Resistant) | Type C (Very Good Oil Resistant) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Grades& Properties | ARCI - NOR (Non Oil Resistant) |

ARCI - GOR (Good Oil Resistant) |

ARCI - VGOR (Very Good Oil Resistant) |

||||||

| 2 | Grades Offered | ARCI 50A | ARCI 70A | ARCI 80A | ARCI 50B | ARCI 70B | ARCI 80B | ARCI 50C | ARCI 70C | ARCI 80C |

| 3 | Hardness IRDH | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 | 50 ± 5 | 70 ± 5 | 80 ± 5 |

| 4 | Dimensional charge percent Max. | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 5 | Tensile Strength kPa. Min | 650 | 900 | 1250 | 700 | 1250 | 1550 | 1250 | 1550 | 1900 |

| 6 | Compressibility (at 2800 KPa) Percent |

45-65 | 30-45 | 15-30 | 45-60 | 35-50 | 25-35 | 35-45 | 25-35 | 15-25 |

| 7 | Recovery, Percent, Min | 80 | 80 | 75 | 80 | 80 | 75 | 80 | 80 | 75 |

| 8 | Compression Set Percent Max. | 90 | 90 | 90 | 80 | 85 | 90 | 80 | 85 | 90 |

| 9 | Chemical Test on water extracts | |||||||||

| a) PH. where applicable | 5.0 to 8.5 | 5.0 to 8.5 | 5.0 to 8.5 | |||||||

| b) Chloride content(as chloride ion) | 0.2 percent, Max | 0.2 percent. Max | 0.2 percent, Max | |||||||

| c) Sulphate content(as sulphate ion) | 0.2 percent, Max | 0.2 percent, Max | 0.2 percent, Max | |||||||

| 10 | Gaskets suitable for |

General purpose only Light electrical and general automotive industry |

Automotive Industry Light electrical and general automotive industry | Automotive industry Heavy electrical industry Ship building and maintenance Aircraft industry | ||||||

| SR. NO |

Mechanical Properties. | GR/GCS - R & B (Moderate oil Resistant) |

GR/GCS - S & P (Good oil Resistant) |

GR/GCS - I & II (Very good oil Resistant) |

||||||

|---|---|---|---|---|---|---|---|---|---|---|

| RC-50 | RC-70 | RC-80 | RC-50B | RC-70B | RC-80B | RC-50C | RC-70C | RC-80C | ||

| 1. | Hardness IRDH | 50-10 | 70.10 | 80.10 | 50.10 | 70.10 | 80.10 | 50.10 | 70.10 | 80.10 |

| 2. | Dimensional charge percent Max. | 1 5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 |

| 3. | Tensile Strength | 6.63 | 9.18 | 12.75 | 1 7.14 | 12.75 | 15.50 | 12.75 | 15.50 | 19.50 |

| Kg/cm2 (KPa*) Min. | (650) | (900) | (1250) | (700) | (1250) | (1550) | (1250) | (1550) | (1900) | |

| 4. | Compressibility at 28 Kg/cm2 (2800 KPa) |

45-60 | 35-50 | 25-35 | 45-60 | 35-50 | 25-35 | 35-45 | 25-35 | 15-25 |

| 5. | Tpencem45-60 Recovery Percent Min. | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 | 80 |

| 6. | Compression Set Percent Max. | 80 | 85 | 90 | 80 | 85 | 90 | 80 | 85 | 90 |

| 7. | Chemical Test on water extracts | |||||||||

| a) PH. where applicable | 5.0 to 8.50 | 5.0 to 8.50 | 5.0 to 8.50 | |||||||

| b) Chloride content(as chloride ion) | 0.2 percent Max | 0.2 percent Max | 0.2 percent Max | |||||||

| c) Sulphate content(as sulphate ion) | 0.2 percent Max | 0.2 percent Max | 0.2 percent Max | |||||||

| 8. | Volume change after immersion in ASTM oil No 3 for 70 hours |

40 percent Max | 25 percent Max | 15 percent Max | ||||||

The specifications for rubberized cork can vary depending on the specific application and industry requirements. However, here are some common specifications that are often considered for rubberized cork:

| 1 | Thickness | Rubberized cork is available in various thicknesses, typically ranging from 0.8mm (0.031 inches) to 12mm (0.47 inches) or even thicker. The thickness is selected based on the intended use and sealing requirements of the application. |

|---|---|---|

| 2 | Density | The density of rubberized cork is typically specified in terms of grams per cubic centimeter (g/cm³) or pounds per cubic foot (lb/ft³). The density can vary based on the composition and specific application, but typical densities range from 0.40 g/cm³ to 0.80 g/cm³ (25 lb/ft³ to 50 lb/ft³). |

| 3 | Hardness | Rubberized cork is often specified by its hardness, which is measured using a durometer scale. The hardness can be indicated by a numerical value on scales such as Shore A or Shore D. Common hardness ranges for rubberized cork are between 30 and 80 Shore A. |

| 4 | Compression Set | Compression set refers to the ability of rubberized cork to recover its original shape after being compressed. It is typically specified as a percentage and is determined through testing. Low compression set values indicate better resilience and sealing performance. |

| 5 | Tensile Strength | Tensile strength measures the maximum stress a material can withstand before breaking or deforming under tension. It is typically specified in units of megapascals (MPa) or pounds per square inch (psi) and is determined through standardized testing methods. |

| 6 | Chemical Resistance | Depending on the application and the substances it may come into contact with, rubberized cork may have specific chemical resistance requirements. This can include resistance to oils, fuels, solvents, acids, or other chemicals. The specific chemical resistance specifications will depend on the intended use and the substances involved. |

| 7 | Other Specifications | Depending on the application, additional specifications may be relevant. This could include specifications related to temperature resistance, flame resistance, electrical insulation properties, dimensional tolerances, and specific industry standards or certifications. |

It is important to consult with the manufacturer or supplier to determine the specific specifications and requirements for rubberized cork based on your intended application and industry standards.

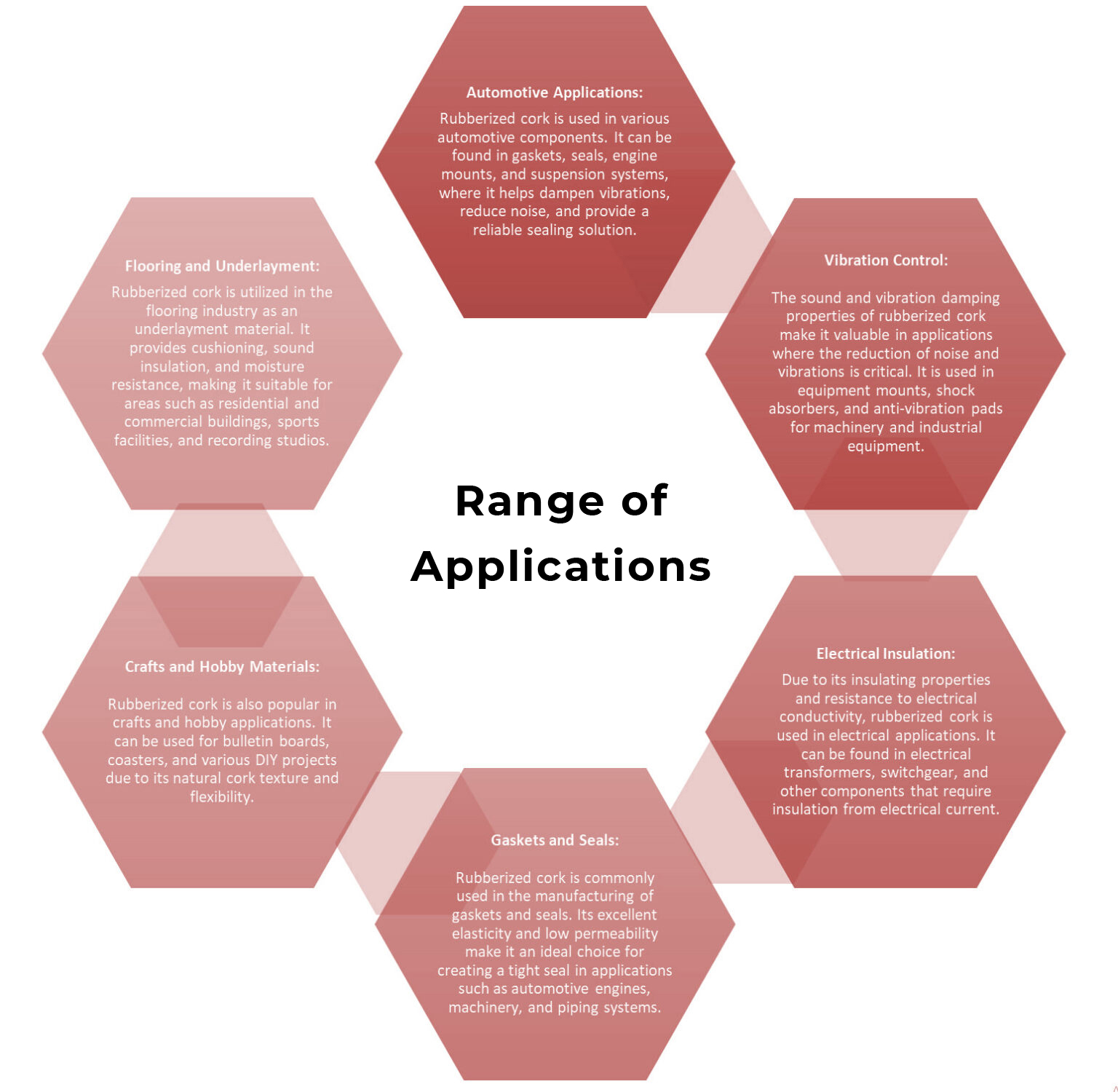

The key features of rubberized cork include elasticity, durability, low permeability, chemical resistance, and sound/vibration damping. These properties make it suitable for a wide range of uses:

Overall, rubberized cork offers a unique combination of properties that make it a versatile material for applications requiring sealing, insulation, vibration control, and sound absorption. Its usage spans industries such as automotive, electrical, construction, and crafts, among others.

We are a client centric organization, hold expertise in providing customized range of Cork and Rubber Cork Products to our clients. These products are widely used in various industries and acknowledged for their quality, flexibility and efficiency characteristics. Our range is tested on various quality parameters that meet industry standards.

We are backed by a team of experienced professionals who enable us in meeting the bulk demand of clients within a committed time frame. Moreover, our timely delivery services, transparent dealings and superior range have helped us gain a vast client base across the globe.

Being a customer centric organization, we follow ethical business policy and transparent transaction practice in a zest to attain maximum customer approval and satisfaction. Quality of the offered range of corks and gaskets is never compromised at our end. Determined to attain maximum customer approval, we assure timely delivery of the offered range of the corks and gaskets at the customers’ end. Customized centric approach is followed while dealing with the customers, to understand and meet different requirements of our customers.